Categories

New products

-

Lens Ring Joint Gasket

With professional Lens Ring Joint Gasket factory, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading China Lens Ring Joint Gasket manufacturers and suppliers.

-

Double Jacket Gasket

With professional Double Jacket Gasket factory, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading China Double Jacket Gasket manufacturers and suppliers.

-

Corrugated Gaskets

With professional Corrugated Gaskets factory, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading China Corrugated Gaskets manufacturers and suppliers.

-

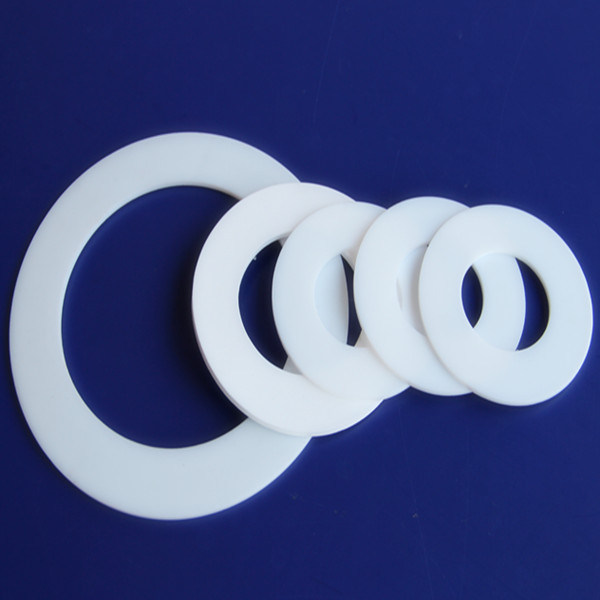

PTFE Envelope Gasket

With professional PTFE Envelope Gasket factory, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading China PTFE Envelope Gasket manufacturers and suppliers.

-

Rubber Sheet

With professional Rubber Sheet factory, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading China Rubber Sheet manufacturers and suppliers.

-

-

Gasket Reasons for failure

Uneven pressing force is caused by a variety of factors, first is the human factor: asymmetric construction of the preload bolt, this factor can eliminate construction; theory on the flange pressed, the sealing surface is absolutely parallel to the practice, however, the centerline of a pipeline can not be absolutely concentric

-

Gasket Improvements

Many gaskets contain minor improvements to increase or infer acceptable operating conditions:

-

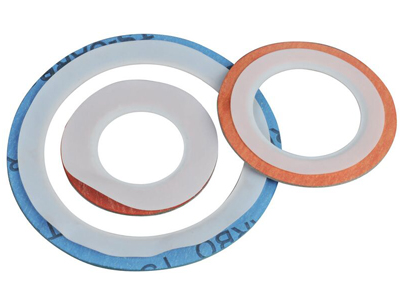

Flange gasket

A flange gasket is a type of gasket made to fit between two sections of pipe that are flared to provide higher surface area. Flange gaskets come in a variety of sizes and are categorized by their inside diameter and their outside diameter. There are many standards in gasket for flanges of pipes. The gaskets for flanges can be divided in major 4 different categories:

-

Kammprofile gaskets

Kammprofile gaskets are used in many older seals since they have both a flexible nature and reliable performance. Kammprofiles work by having a solid corrugated core with a flexible covering layer.

-

Double-jacketed gaskets

Double-jacketed gaskets are another combination of filler material and metallic materials. In this application, a tube with ends that resemble a "C" is made of the metal with an additional piece made to fit inside of the "C" making the tube thickest at the meeting points.

-

Constant seating stress gaskets

The constant seating stress gasket consists of two components; a solid carrier ring of a suitable material, such as stainless steel, and two sealing elements of some compressible material installed within two opposing channels, one channel on either side of the carrier ring.

-

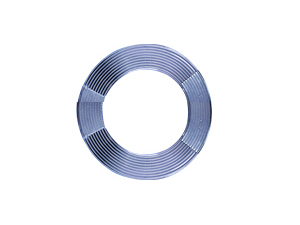

Spiral-wound gaskets

Spiral-wound gaskets comprise a mix of metallic and filler material. Generally, the gasket has a metal (normally carbon rich or stainless steel) wound outwards in a circular spiral (other shapes are possible) with the filler material (generally a flexible graphite) wound in the same manner but starting from the opposing side.

-

Solid material gaskets

The idea behind solid material is to use metals which cannot be punched out of sheets but are still cheap to produce. These gaskets generally have a much higher level of quality control than sheet gaskets and generally can withstand much higher temperatures and pressures.

-

Sheet gaskets

The premise is simple in that a sheet of material has the gasket shape "punched out" of it. This leads to a very crude, fast and cheap gasket. In previous times the material was compressed asbestos, but in modern times a fibrous material such as high temp graphite is used.